Products:

Ductile iron pipe`s coatings and linings

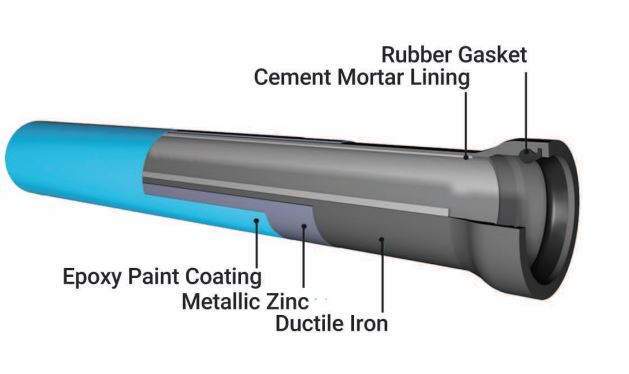

Pure metallic Zinc (99,99% Zn):

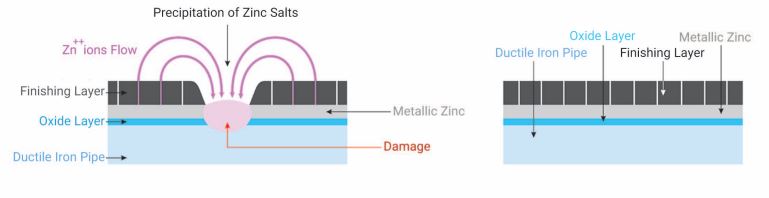

Zinc coating is one the most common types of coating used for ductile iron pipes, which is applied along with the final coating. Zinc is an active element in electrochemical table acting as a scrificial anode of occurring damage on coating and prevets from rusting the metal inner layer. Relying on this specification, the external surface of ductile iron pipes are coated using thermal spray method according to ISO 8179-1 standard.

The minimum amout of zinc coating on external surface of pipe is 200 gr/m2. In the following picture, the protection mechanism of metal zinc coating is presented schematically.

Zinc-Aluminium (Zn-15% Al):

Based on recent researches, Aluminium can rendrea passive film on iron surface while metal zinc can result in galvanic protection. Thus, a coating of Zinc-Aluminium alloy (Zn-15% Al) is able to act quite properly as a coating for ductile iron pipes working on various environments. The presence of two metals simultaniously, leads to combine their advantage which eventually forms a resistance and powerful coating against corrosion.

In order to reach protective charasteristic according to ISO 8179-1, a Zn-Al coating has to be applied with amount of at least 400 gr/m2 on the external pip`s surface.

Black Bituminous Coating:

In order to increase resistace against corrosion of soil and other environmental factors, bituminous paint with minimum thickness of 70 microns is sprayed uniformly on the outer surface of pipes.

In special cases when there is a request for higher corrosion resistance, like using pipes against UV emission such as in above-ground pipelines, there is possibility to use bitumen coating with maximum of 20% aluminium.

Blue or red epoxy coating:

Epoxy paint is a two-component coating based on special epoxy resin and polyamide hardener. Appling a single layer of epoxy coating, according to ISO 8179 standard, on the surface of pipe which forms a resistant film against corrosive agents. After completion of the epoxy paint reaction, it makes a very hard surface that shows great resistance to scratches, abrasion and chemicals. Epoxy paint coating is applied on the surface of ductile iron pipes after Zn or Zn-Al.

Advantages of epoxy coating:

- High resistance against chemicals and corrosives

- Proper mechanical and thermal charasteristics (high temperature resistance)

- High stability and adhesion

- Great resistance against abrasion

- Electrical insulation

Cement mortar lining

One of the most common lining of ductile iron pipes is cement mortar. Self-healing is considered as the most unique advantages of this lining. Cement mortar lining is applied by centrifugal method, then curing is carried out in an appropriate temperature and humidity condition. From among ist advantages, one ven mention high density, minimum roughness and adequate adhesiveness. The smooth internal surface can cause higher flow rate and less pressure drop and as a result raise hydraulic efficiency of water.

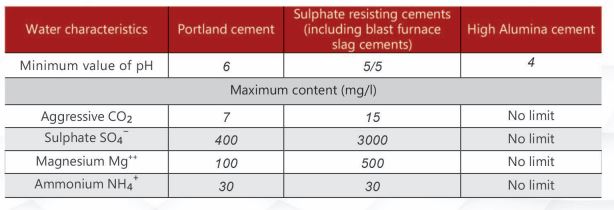

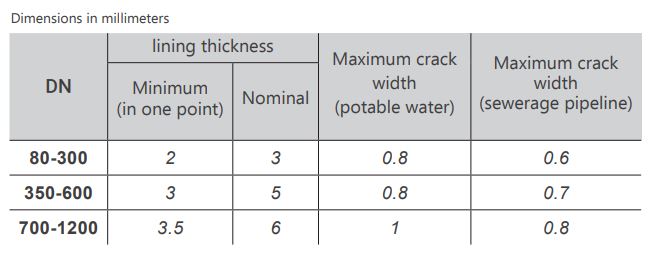

Charasteristic of cement mortar layer in accordance with ISO 4179 are given in the following table:

Different cement lining of ductile iron pipes:

HANYCO ductile iron pipes could be lined with different kinds of cement layer according to EN 545 or ISO 2531 standards.

- Portland cement (anti-sulphate)

- Blast furnace slag cement

- High alumina cement (for sewage application)

Charasteristics of each cement lining based on EN 545 are given in the following table: